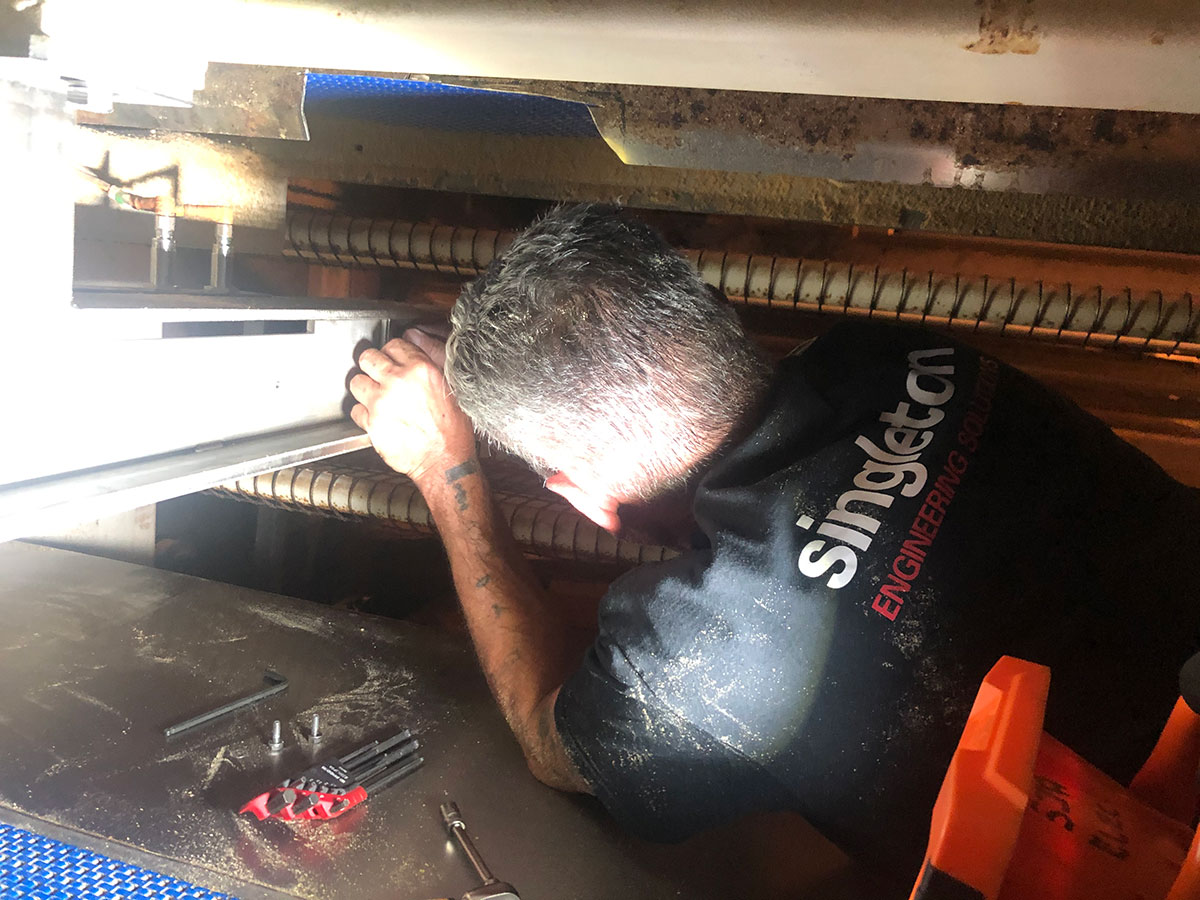

Maintenance and Inspection

Planned or preventative maintenance inspections are typically carried out annually to review the performance and efficiency of machinery, and identify any required repairs.

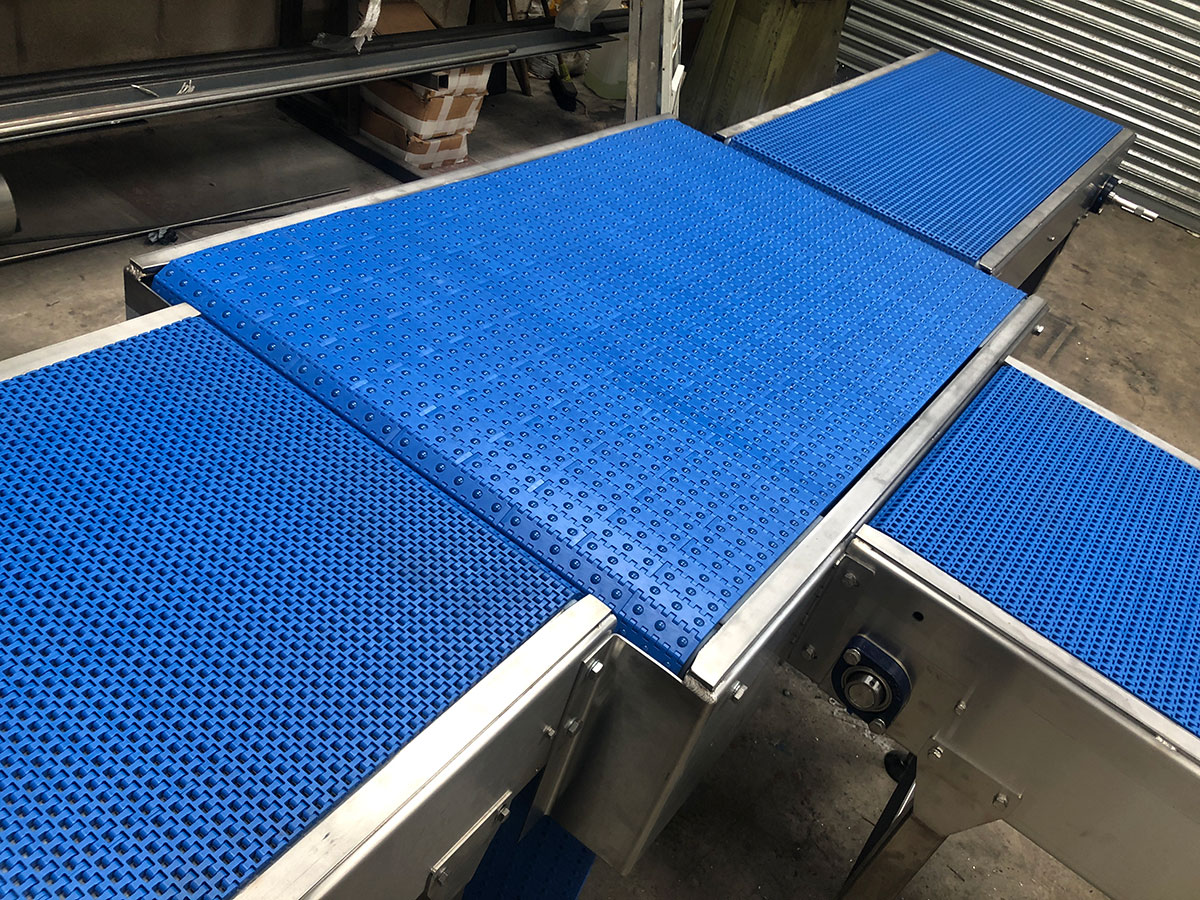

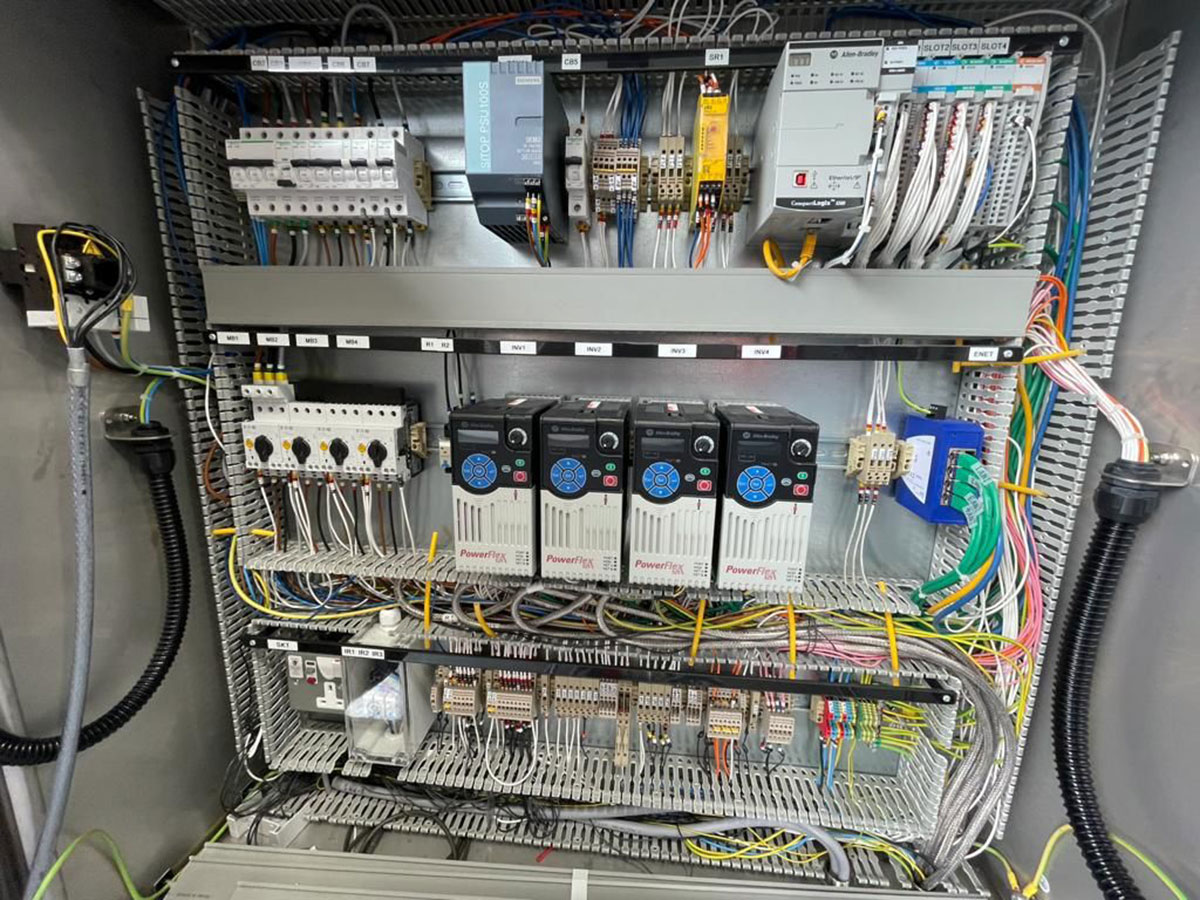

Singleton’s expertise includes maintaining and inspecting commercial ovens, proovers, coolers, extrusion machines, material handling systems, flood defences and water control systems. Regular inspections and preventative maintenance strategies can be developed for any machinery across any sector with minimal disruption to your operations.

Singleton Engineering have a forward-thinking approach to Preventative Maintenance (PM) by implanting strategies with regular inspections into the performance of plant equipment. Using a PM strategy can help to reduce unexpected spending on repairs by highlighting where machines can be more streamlined to prevent unexpected breakdowns.

Planned or preventative maintenance inspections are typically carried out annually to review the performance and efficiency of machinery, and identify any required repairs.

Singleton’s expertise includes maintaining and inspecting commercial ovens, proovers, coolers, extrusion machines, material handling systems, flood defences and water control systems. Regular inspections and preventative maintenance strategies can be developed for any machinery across any sector with minimal disruption to your operations.

Singleton Engineering have a forward-thinking approach to Preventative Maintenance (PM) by implanting strategies with regular inspections into the performance of plant equipment. Using a PM strategy can help to reduce unexpected spending on repairs by highlighting where machines can be more streamlined to prevent unexpected breakdowns.